Skyway Bike Serial Numbers

June 29, 1987 AFA contest Madison Square Garden When it was time for my run, I put the butterflies out of my stomach, bowed my head down, and cranked toward the quarterpipe. A slew of can-can look-backs, switch-handers, no-footers, no-footed can-cans, and everything else in my arsenal poured out of me. Out of nowhere, the arena burst to life with applause and camera flashes.

I won 14-15 expert Ramps and lost the five dollars to Page. Before I'd caught my breath after my run, the team managers from Skyway and Haro had approached with sponsorship offers. Haro wanted to try me out on their B-team, and let me work my way up. Skyway didn't operate like that - I would be part of the their factory squad and get to go on tour, get flown to contests, and draw a salary.

I signed on the line with Skyway and was soon flown to their headquarters in Redland, California. The team manager had been hyping my skills, and the owners wanted to witness their new kid in action. During the show I slammed so hard I snapped my other collarbone and wound up in the hospital again. Luckily, they decided to keep me on the team. The Ride of My Life - Matt Hoffman p 34-35.

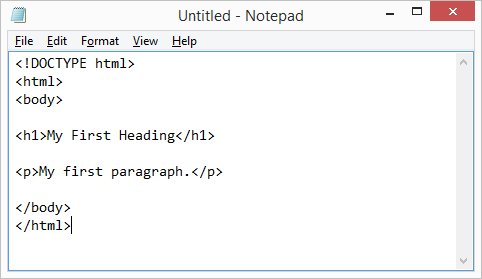

These were on a 1985 Skyway Street beat show bike. These are original lavender 80's skyway mags with the serial numbers engraved as seen in picture #10.

According to his book, Skyway wanted Mat to turn pro, but he didn't want to, so he switched to Haro prior to the summer tour in 88. Rhino had resigned as the skyway team manager and was going back to work for Haro, his brother Bob's company. For years, I'd wanted to ride for Haro - the first company to create a freestyle bike, run by the guy who invented the sport. It was a pure respect thing.I made a phone call to Rhino and secured a spot on the Haro team. I would remain classified as an am for at least the rest of the year, but I got a pay increase and was making about $50,000 in annual salary - approximately 10 times what I earned with Skyway. The Ride of My Life, Mat Hoffman p 57 Sorry for the derail, Lee.

Back to the Skyway TA matter. As far as i know, the first skyways were produced in japan in late 82 / early 83. The 1983 usa made ones have a curved brake bridge and are avilable in chrome only. They are dated by month and year and have a sequential serial number on the bottom bracket. The 1984s and 1985s were available in white and chrome and have the month and year and a sequential serial number on the bottom bracket.

I don't believe any were produced in 1986 or with a 1986 date on the bottom. I've been told that they had plenty left over from 1985 and did'nt need to produce any more to meet demand. I've never seen a ta dated 1986. If anyone has a 1986 that is verifiable i'd be interested in seeing it. (i've spent some time searching the net and have never seen one nor have i ever seen one in person) someone might be more knowledgeable than i am but these are the things i believe to be true.

As far as i know, the first skyways were produced in japan in late 82 / early 83. The 1983 usa made ones have a curved brake bridge and are avilable in chrome only. They are dated by month and year and have a sequential serial number on the bottom bracket. The 1984s and 1985s were available in white and chrome and have the month and year and a sequential serial number on the bottom bracket. I don't believe any were produced in 1986 or with a 1986 date on the bottom.

Bicycle Serial Numbers

I've been told that they had plenty left over from 1985 and did'nt need to produce any more to meet demand. I've never seen a ta dated 1986. If anyone has a 1986 that is verifiable i'd be interested in seeing it. (i've spent some time searching the net and have never seen one nor have i ever seen one in person) someone might be more knowledgeable than i am but these are the things i believe to be true.

Later, rob That sounds about right from what I've heard. And they Must have had a crap load left over to have enough to supply Vic and the Dirt Brothers with a whole bike line to sell. Skyway TA's: Skyway TA frame and fork.

(From Boxline69) - BMX Plus! December 1982: The official word from Skyway was that the company worked on the development of the frame for over one year. Initially; according to Craig Raudman of Skyway, once the decision was made to produce the T/A frame, it took quite a search to find someone to produce the unusual tear-drop shape they needed. After looking everywhere in the United States, Skyway finally turned to Japan, where they found two factories capable of producing the special chrome-moly tubes. The Ishiwata Seisakusho Co. Of Japan ultimately won the job, and we must say, the job they did was flawless.

There were two ways to make the odd-shaped tubing. It could be drawn through a die in the desired shape or, as in the case of the Skyway tubing, it could be drawn round then shaped in a forming die. Once the tubing was dialed in, welding it all together in the right angles became the next step. The trick for Skyway was to figure out geometry that would work as well for the huge Andy Patterson as it would for the quick and nimble pro, Bob Medrano.

According to Craig Raudman, countless hours of cutting and redesigning went into the prototypes. With the.geometry finally nailed down, Raudman hopped a plane for Japan to get the final manufacturing specs on the tubing settled. As of this writing, the frames are being completely produced in Japan. The forks are welded then shipped to this country, where Skyway gives them special treatment which involves annealing, re-heat treating, and plating.

According to Craig, this is done in order to assure and verify that the fork is up to spec. BMX Action january 1984: It's obvious from first glance that they invested tons of time and effort putting together the T/A frame and fork (T/A stands for Totally Aerodynamic).

Completely 4130 chrome-moly, the frame and fork are things of beauty - almost masterpieces. Let's start at the back of the frame and work our way forward.

The rear dropouts are not your basic snooze-a-roonie variety. They're die-cut into a very distinctive shape, knurled on the outside to give the axle nuts somethin' extra to grab onto, and they have a zoot tookin' hole punched out above the axle slot to add a little extra class.

The seat and chain stays are tapered, teardrop-shaped tubes that go through a manufacturing process that makes the wall thickness of the material thicker where the taper is narrow, and thinner where the taper is wide. The bottom ends of these tubes are slotted to accept the dropouts, and then the ends are completely closed and welded on both sides of each dropout. The welding throughout the frame and fork is first-rate! Totally clean beads with apparently good penetration. Definitely some of the nicest we've seen in a long time.

The seat tube is round at the top, and then below the clamping area it is expanded into a teardrop shape. The top and down tubes use 1 1/2 inch teardrop-shaped material. The four inch head tube is milled on the inside to provide the cups a perfect fit. By now, you're probably wondering about the frame weight. Well, it tipped the outstandingly accurate Mighty BMXA scales at 4 pounds.

Skyway Bike Company

Okay, let's scrutinize the fork. The legs are made of 1 1/8 inch teardrop tubing, and the bottoms have been cleanly cut, formed, and welded shut. The dropouts are styled similar to the rear dropouts, all the way down to the tightening hole and the knurling for extra axle nut gription. The collar is drilled for a front brake. One of Skyway's goats for the forks was to make them light, and at 1 pound, 8 1/2 ounces, they did it. But they also wanted them to be able to take extreme punishment. So they went a big step beyond average manufacturing processes by completely heat-treating them after welding to between 30 and 36 on the Rockwell hardness scale.

What this means is that these forks are tough! Since parts are subjected to very high temperatures during the heattreating process, they tend to warp. But Skyway puts their forks into special jigs to make sure they don't lose their shape. After they come out of the oven, the forks are carefully examined to make absolutely sure they're straight.

The wheelbase is adjustable from 35 3/4 to 37 inches, so it should fit radsters 14 and over very nicely. Now that you have the full scoop, do ya wanna take a stab at the sticker price of all this.

Forget it, we'll tell ya. That even includes a Skyway California Lite frame pad. Pretty cool price for the goal involved.