Chopper Frame Blueprints Pdf Viewer

Chopper Frame Blueprints Pdf Viewer In 2013 someone crashed the Murcielago and it took four years and $167,000 to get back on the road. Between the repairs, maintenance, insurance and fuel, the grand. Manage your page to keep your users updated View some of our premium pages: google.com. Upgrade to a Premium Page. Warrior Recumbent Tadpole. There are some great kits available for mini choppers. There are frame kits, front end kits, and full bike kits. How To Build A Mini Chopper Author: Owner.

This is an instructable on how to build a chopper bike on a budget. The main inspiration for this came from AtomicZombie and Koolkat's instructables. I've recycled as many parts as possible, and used scrap materials when I could.

I took a 25 year old Raleigh Wisp ladies racing bike and converted it to something a bit out of the ordinary. Materials needed:.Donor bike.Welder (I used a gasless MIG welder - a Clarke 105EN).Steel tube(s) for the forks. These need to be quite heavy gauge as the forces involved will tend to bend the tubes.Steel tubing to extend the frame after chopping. The diameter of this tubing should be either slightly smaller than the existing frame tubing (to fit inside the cut tubes) or slightly bigger (to fit over the tubing). Butt welding tubes of the same diameter is more difficult and will not be as strong unless your an expert welder (and I'm not!).Some sheets of steel. I had some 1.4mm thick sheet steel which is perfect for the plates I made.New chains - if you're extending the frame significantly, the chain length will also increase. Buy two cheap chains to join together.Access to a pipe bender - you may need this if your angles change significantly and you don't want to cut the extension tubes at an angle.

Read on for instructions on how I did it, and the mistakes I made along the way. Above all, enjoy building and don't give up!

Right now, our forks are just two tubes. There's no way of attaching them to a wheel, so we need to make some drop-outs. Pic 1 shows what we want to achieve. The drop-outs need to be strong. I used some scrap steel plate, about 3mm thick. This is ideal. Overlay one of the existing fork's drop-outs onto the steel to be cut.

This will give an indication of the size and shape of the piece to cut out. Use an angle grinder to cut out two pieces from the steel to form the drop-outs. Angle grinding is never exact, so the drop-outs were not exactly the same.

I aligned the drop-outs in a clamp and used the grinder to get their edges identical. Pic 4 Use the grinder to make the edges neat. Remember, the straighter the surface, the better the join will be. Clamp the two pieces together and cut out the slots for the wheel axle.This way, you can be sure that when you use an angle grinder to cut the slots, both slots will be identical.

Take your time here - don't cut too much of you'll risk the wheel popping out. Your aim here is to cut a slot just big enough for the wheel's axle to fit snugly. Keep trying to fit the wheel axle into the slots until they just fit. A tight fit is needed - not a lose fit. (Pic 6) Next, we need to weld the drop-outs to the forks. I used a magnetic mount to hold the drop-out to the fork.

IMPORTANT: I made a mistake when I welded my dropouts - I placed them right in the centre of the tube - I should have moved them closer to one edge. I only discovered this later during a test ride when a wheel's spokes were rubbing against the inner side of the fork tubes. Luckily, I was able to use another wheel which fitted better, but take heed of this mistake!

Free A Frame Blueprints

Tack weld the drop out to the forks. Check your alignment.

When your happy that all is well, weld it securely. Here's where the time taken to make a straight edge pays off! Ok, we have our two tubes and we've welded drop-outs onto them. My plan is to be able to bolt a steel plate to the tops of the forks, so we'll need to work out a way of being able to screw a bolt into the forks. Next step - make a threaded top for the forks.

First of all, you'll need to get some nuts, bolts and washers. I bought a pack of M10 bolts, nuts and penny washers. All these are M10 size (10mm hole).

These are really cheap from any hardware discount store. Assemble a bolt, washer and nut as shown in the first picture. Weld each face of the nut to the washer.

Download sqlite editor for android. This is a versatile editor of SQLite database on Android device. User can browser, open and edit SQLite files. User can read the data of all tables. Recently opened database feature for convenience. Also, you can create a new database. WE HAVE FIXED ADS ISSUE IN THE LATEST RELEASE. NOTE:- SOME TYPICAL. Download the 4.2☆ SQLite Editor 2.2.1 at Aptoide now! ✓ Virus and Malware free ✓ No extra costs. Sqlite Master is the ultimate Sqlite database editor for users on Android. Using Sqlite Master you can do almost anything in a Sqlite database. Functionality includes table data browser/editor/modification, query editor, table export, CSV import and lot more and root access. Compare to other available SQLite apps, this is.

Remove the bolt, so you'll be left with a welded nut and washer as shown in the second picture. Finally, weld the washer/nut to the top of the fork. Now you should have a solid mount on the top of the forks This will enable us to screw a bolt into the forks. Let's move on. To recap - at this stage we have two tubes. Each tube has a drop-out on one end and a threaded nut at the other end. Next step: Build the forks Cut the legs off the forks.

Try and get the base at flat as possible. Using a bit of cardboard as a template, draw a semi circle around your new fork tubes. Use a marker to draw the shape of the new forks on the fork crown. Use an angle grinder to cut the shape of the new forks out of the crown. Take your time here, try and get the shape as close as possible to the new forks. Attach the wheel to the ends of the forks. This will give use the correct width for the forks.

Next, place the steerer tube / crown between the forks. If you've been careful, it should fit snugly. Using another bit of cardboard, mark and cut holes where the three tubes fit. This will form the template which we'll use for the base plate and the top plate. Trim the cardboard so it's a nice neat shape. Make the base plate: Using the cardboard template, cut a shape from some sheet steel. I used some scrap 1.4mm sheet steel.

Draw the two outer holes (where the forks go) onto the sheet steel. Use an angle grinder to cut the sheet steel so you have a base plate as shown in picture 3.

Tack weld the base plate to the fork crown. Be careful not to get any weld spatter on the bearing races! Next we have to make a stem. If you like, you can cut the head off the existing stem. I've chosen to make my own stem, as I had some steel pipe which fits inside the fork's steerer tube. Use the angle grinder to cut a 45 degree cut on the end of the tube.

Cut the tube so that its length is correct for the steering bolt and wedge. We've now made our own stem. If you cut the head off the existing stem, you can skip the above steps.

Fit the new stem into the fork's steerer tube. Position the steerer tube / crown between the forks once more. If you have a friend, they can help you hold everything together. I've used a strap to hold everything together. The upper headset nuts should be about an inch below the top of the forks. When everything is nice and centered, weld the base plate to the forks.

OK, now we have our two fork tubes which are welded to the steerer tube / crown. Next we need to make a top plate which will clamp everything together. We will re-use the cardboard template we made previously to cut out a shape in sheet steel. Now we need to mark on the sheet steel the centres of the two forks and the stem bolt.

I'm using 10mm bolts so I drilled 15mm holes at the fork centres, and about 10mm hole for the stem bolt. It doesn't matter if the holes are bigger than the bolts, we'll be using washers when we assemble it. Picture 1 shows the drilled top plate. Picture 2 shows the plate bolted to the top of the forks. (Ignore the clamp that the bolt is holding - we'll discuss that later) Summary - we've now built our forks.

Our tubes are welded to our base plate, which in turn is welded to our fork crown. We've made a top plate and proved it fits OK by bolting it all together.

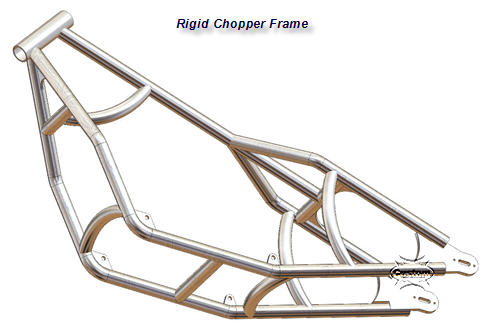

Picture 3 shows the bike assembled with our forks. Well, the forks look OK, but we'll have to seriously modify the frame to make it rideable. Next step - the frame. Think long and hard about what you're going to do with the frame. It took a lot of thinking to make sure that my frame chop was going to work. In the end, it worked out OK.

Picture 1 shows the frame before chopping (it's upside down on the bench) The frame was chopped to that the bottom bracket shell was towards the front of the bike. We'll be stretching the frame. Picture 2 shows the frame after the chop! There's no going back now!

I decided I wanted to keep the twin top tubes as they're such a great feature, so I cut them as near to the rear hub as possible. Picture 3: The next step is to mock up the bike with the new frame design. It's important to put the wheels on so you can get the height correct. For this mock up, I supported the bottom bracket and extended the frame with some thin scrap tubes. I noticed that the twin top tubes were too low so I took a chance and bent them by hand to the correct height for the seat.

If I damaged them (split the joint, etc), I would have had to weld them to repair them. As it was, I got away with it. I was happy with the overall shape and design of the new frame, so the next step was to extend the frame by inserting two new steel tubes from the bottom bracket shell to the bottom pair of tubes at the bottom of the seat post. For this task, I used the measurements from the mock up to cut two lengths of tube.

I used a pipe bender to make a slight bend near the bottom bracket shell. This was necessary as the down tube angle had changed. Picture 4 shows this clearly.

At this stage, the seat tube is not attached to anything - it's just floating. The next step is to secure the bottom of the seat tube. Using a piece of cardboard as a template, I made a plate of sheet steel which I positioned underneath the seat tube.

I welded the plate on top of the horizontal tubes. This strengthens the joint between the two new tubes and the rear tubes.

I then welded the seat tube to the plate. Next, let's turn our attention to the top tubes. Again, these are just floating - they're not attached to anything yet. Again, I made another plate from sheet steel.

You can't see it, but I used the angle grinder to make a slot in the seat tube. I inserted the steel plate into the slot, then tack welded the plate to the seat tube. This slot means the joint will be a lot stronger and there will be less downward stress on the weld. Next, I welded the two top tubes to the steel plate. The frame needs some more strengthening. The next step is to join a new piece of steel tube from the bottom bracket shell to the top tubes.

This will replace the seat tube which is now towards the back of the frame. Using the same trick of making a cardboard template, I made a steel sheet plate and welded it to a new piece of steel tubing. It took several attempts to get the angle correct, so use a small tack weld and be prepared to break / grind / re-weld.

Be careful with the length of the tube - if it's too long, it will hit the bottom bracket axle. Make sure the tube fits into the bottom bracket shell, but not too far in. Picture 2 shows the frame, fully welded. I'm going to take full advantage of the twin top tubes, and mount a seat on top of the tubes. The seat is going to be a simple construction of scrap wood, scrap foam and scrap leather. Picture 1: I screwed two pieces of scrap wood together, then drilled holes in the wood through to the plates below. I used some bolts and nuts to check it fitted OK.

Now for some upholstery! Picture 2: I used a heavy-duty staple gun to staple some foam to the wood.

Picture 3: Again, use the stapler to staple leather scraps to the seat. Next step is to fit the handlebars. You have three choice with the handlebars 1.

Use the existing handlebars. In my case, they're racing drop-handlebars, so they're not suitable. Make your own. If you have some steel tubing you can either make your own bars using a pipe bender or by cutting and welding into the right shape 3. Use other bars. I had some scrap motorcycle handlebars, so I decided to use these. I used the seat from the donor bike, and removed the seat clamp from underneath the saddle.

Picture 1 shows the seat clamp loosely assembled around the handlebars. It's a pretty good fit so we'll go with these. Picture 2: Next we position on of the seat clamp grips onto our top plate we made earlier. Picture 3: Tack weld the seat clamp plate to the top plate Picture 4: Weld the seat clamp to the top plate and assemble the seat clamp around the handlebars. We now have a fully adjustable handlebar clamp. If you use the same wheels that came with the bike, you won't have to bother with this step.

I wasn't happy with the 27 inch wheels thats the bike came with. I decided to change them for sturdy 26 inch mountain bike wheels.

For this to work, I had to alter the brake hanger. IMPORTANT: Shield the tire with a wet cloth or it will be damaged by the heat from the welder! Picture 1: I worked out where the brake caliper had to be mounted and tack-welded a section of plate across the rear chainstays. Note that the mounting hole is not central, this is due to errors in my frame alignment. Picture 2: Check the brake caliper fits and functions correctly by hand before final welding. Picture 3 shows the welded plate and the caliper mounted.

I used a spare brake lever I had from another bike.